Green Energy

Platecoils® make excellent green energy heat exchangers — your practical choice for renewable energy service. With temperature approaches in the 1–2°F range, plate HEs take better advantage of lower-grade waste heat than S&Ts. And, they are easier to clean, take up less space and require lighter support structures. Multiple designs offer the versatility to answer your application needs.

PHE Applications

- Biomass dryer heating banks

- Batch hydrolysis vessel heating surfaces

- Evaporator heating banks

- Evaporator economizers

- Economizing and heat recovery

- Blow heat recovery

- Yeast coolers

- Beer/mash interchangers

- Thermal control of fermentation

- Vent condensers

- Distillation column heating surfaces

- Syrup condensers

- Ethanol preheaters

- Molecular sieve regeneration condensers

- Anhydrous condensers and coolers

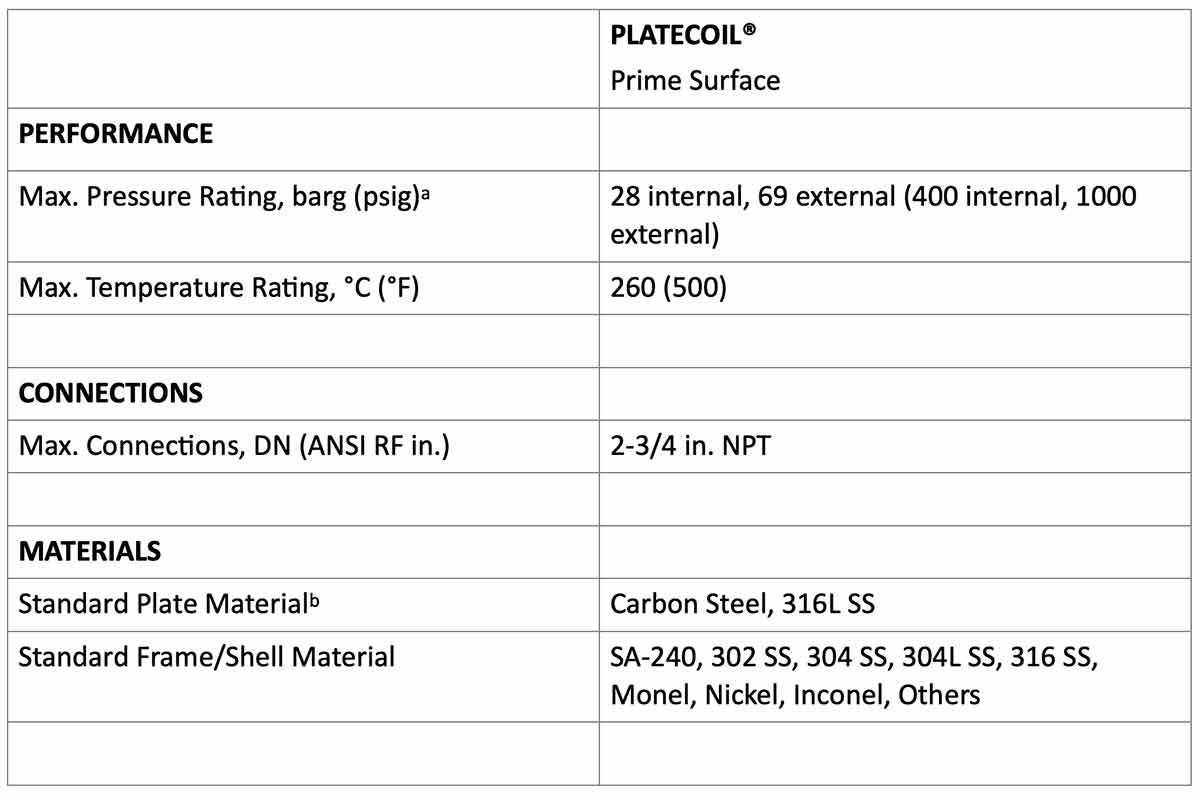

PLATECOIL® Prime Surface PHE Standard Range General Specifications

a Ratings offered as a general guide only. Certain combinations of physical and fluid properties may affect individual product specifications. Contact the factory with your specific application data.

b Higher performance materials are available.

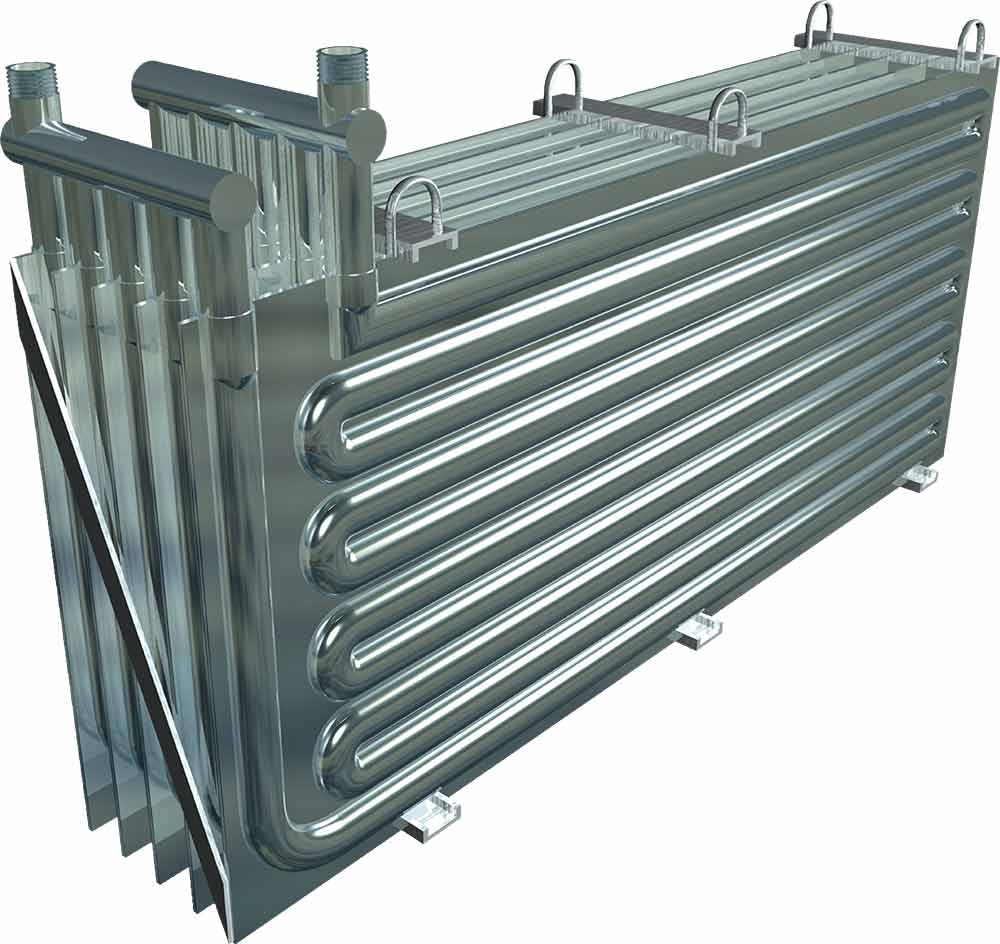

PLATECOIL® Prime Surface

- Panels can be formed into vessel shells or jackets

- Pre-engineered bank modules include piping, supporting structure and manifolds

- Configurations for steam applications offer high flow rates and low pressure drop

- Liquid types accommodate maximum velocities and high heat transfer capabilities at low-to-moderate flow rates

PLATECOIL® Prime Surface HE banks

- Highly efficient in tank heating/cooling and flue gas cooling/heat recovery.

- Proven in pond geothermal heating/cooling service.

- Formable into banks, vessel shells or jackets.

Acid Hydrolysis Cellulosic Cooking

Heated vessels in this continuous process can be fabricated using PLATECOIL® heating banks as immersion heaters. These include both first- and second-stage hydrolysis vessels and the acid reconcentrator tower. PLATECOIL® banks can also be configured as air heaters in systems such as the biomass dryer.

PLATECOIL® banks find widespread use in tank heating, flue gas cooling and heat recovery.