Econocoil ®

Delta T Thermal Solutions ECONOCOIL® is a very efficient and versatile light-duty plate-type heat exchanger. Its unique construction enables high heat transfer efficiency for heating and cooling, which can be applied to a wide range of applications. Units are commonly used in the plating, metal finishing, chemical processing, pulp & paper, waste treatment, textiles, pharmaceutical, and food & beverage industries.

ECONOCOIL® is fabricated from two sheets of metal using a fully computerized welding machine that uses electric roll spot resistance welding. The plate is then hydraulically inflated, forming a variety of flow patterns. Each ECONOCOIL® plate is designed and constructed to match the needs of each application and requirement.

We form in all types of malleable metals – carbon steel, titanium and others.

ECONOCOIL® Applications

- AImmersion Heaters and Coolers

- Jacketed Tanks and Vessels

- Clamp-On Upgrades

- Heat Recovery Banks

- Fluidized Bed Banks

- Cryogenic Shrouds

- Cascade Coolers

- Freeze Dry Condenser Banks

- Shipboard Heaters and Coolers

- Storage Tank Heaters Shelves

- Glycol Dehydrators

- Paint Solvent Coolers

- Water-Cooled Shields for Electric Furnaces

- Water Chillers for Soft Drink Carbonators

- Valve Warmers

- Banks for Waste Heat Recovery

- Refrigeration coolers

- Refrigerated Liners for Medical Testing Machines

- Suction Heaters

- Screw Conveyer Troughs

- Bayonet Heaters

- Drum Warmers

- Pipe Coolers

- Gas cylinder heaters

- Sanitary/hygienic processing

One of the best benefits of ECONOCOIL® is that it can be produced in an extensive range of custom-made variants when needed for special applications. For example, Delta T Thermal Solutions can alter the connection location and length, creating an irregular-shaped curved ECONOCOIL® to fit a tank cone end. Another application example is Delta T staff can weld several plates together to form banks which can be used for large heat exchanger duties and provide accessories to assist with installation and maintenance.

Double Embossed ECONOCOIL®

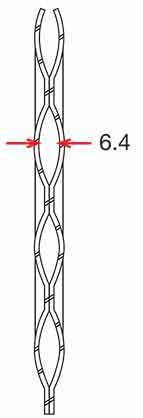

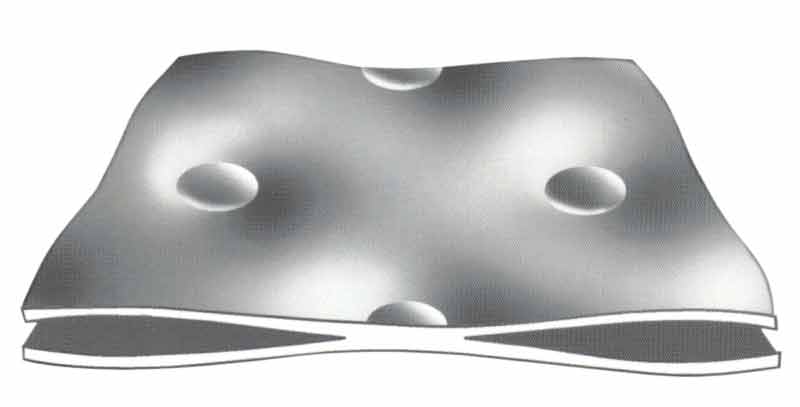

There are two main types of ECONOCOIL®, which determine the unit’s structure. These are double embossed and single embossed.

Double embossed units are made from two sheets of the same thickness, so when inflated, both sheets expand and form a symmetrical structure. These are generally used for internal tank heating plates and banked units.

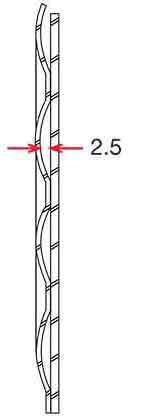

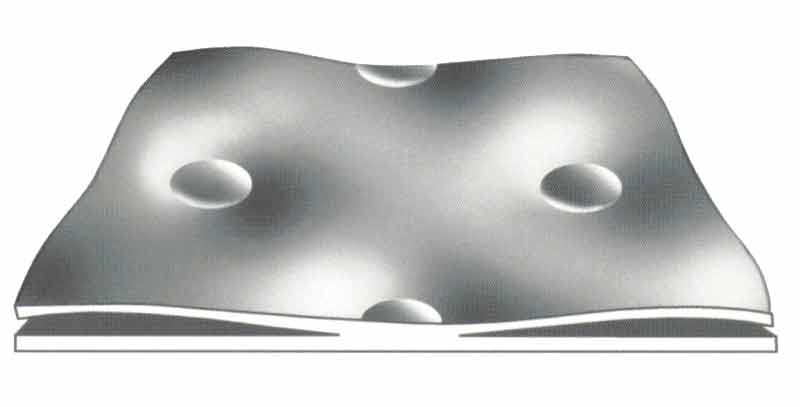

Single Embossed ECONOCOIL®

Single embossed units are made from two sheets with different thicknesses. When inflated, only the thinner sheet expands, leaving one side flat. This is ideal for clamping onto tank walls, both internally and externally.

Standard ECONOCOIL® Styles

Delta T Thermal solutions can manufacture ECONOCOIL® in a massive variety of shapes and sizes to suit all purposes. There are five basic styles to fit specific applications, with all styles available in double and single embossed forms in numerous configurations. All units are supplied with BSPT Male Threaded Connections as standard. However, we can provide a variety of connection options. For Styles EC70, EC80 & EC90, the connection size depends on the plate dimensions.

Delta T Style EC50

Style EC50 ECONOCOIL® is largely used for heating and cooling while immersed in tanks. Therefore, its design is most suitable for liquid-to-liquid duties such as heating oil with hot water. Easy lift handles can be attached with hangers available to make installation alongside a tank wall as simple as possible.

Delta T Style EC60

Style EC60 ECONOCOIL® is widely used for high-velocity media to generate a high-pressure drop which gives accelerated heat transfer. It is commonly used with water, hot oil, and direct expansion refrigerants. Handles can be attached along the width to allow tank immersion.

Delta T Style EC70

Style EC70 ECONOCOIL® is designed to be used with steam or condensing gases as the primary media. Handles can be attached along the length or width for tank insertion. The Style EC70 ECONOCOIL® is particularly effective in banked ECONOCOIL® format constructed with common inlet and outlet manifolds.

Delta T Style EC80

Style EC80 ECONOCOIL®’s primary use is for external Clamp-On ECONOCOIL® for maintaining applications. It’s predominantly effective with high flow rate fluids as it creates minimum pressure drop. Clamp-On EC80 Econocoil units are normally supplied with attachment lugs and heat transfer mastic.

Delta T Style EC90

Style EC90 ECONOCOIL® is usually used for immersed tank heating with steam and condensing gases. The connections are situated together to allow effortless access to the tank. Handles can be attached along the length, and hangers are supplied to assist with the easy installation of tan

Unit Zoning

Smaller ECONOCOIL® units are made up of two zones, as shown above in the standard styles. However, when the width is extended to 750 mm and above, additional ‘zones’ are seam welded into the plates to direct fluid flow to all areas of the ECONOCOIL®, thus helping maintain a higher level of heat transfer.

Delta T Style EC50

Style EC50 ECONOCOIL® is largely used for heating and cooling while immersed in tanks. Therefore, its design is most suitable for liquid-to-liquid duties such as heating oil with hot water. Easy lift handles can be attached with hangers available to make installation alongside a tank wall as simple as possible.

ECONOCOIL® EC50 Four Zone

ECONOCOIL® EC60 Four Zone

ECONOCOIL® Construction Materials and Design Pressure and Materials

Delta T Thermal Solutions stocks Stainless Steel 304 & 316L sheets and orders Titanium, especially per purchase. These are standard materials; however, we can supply others on request.

ECONOCOIL® units can be maintained at high working pressures and temperatures – the maximum design pressure is 18 bar while the maximum design temperature is 185°C.

All units are hydro-tested before they are packed and shipped to confirm that they meet Delta T´s high-quality standards.

ECONOCOIL® Accessories & Options

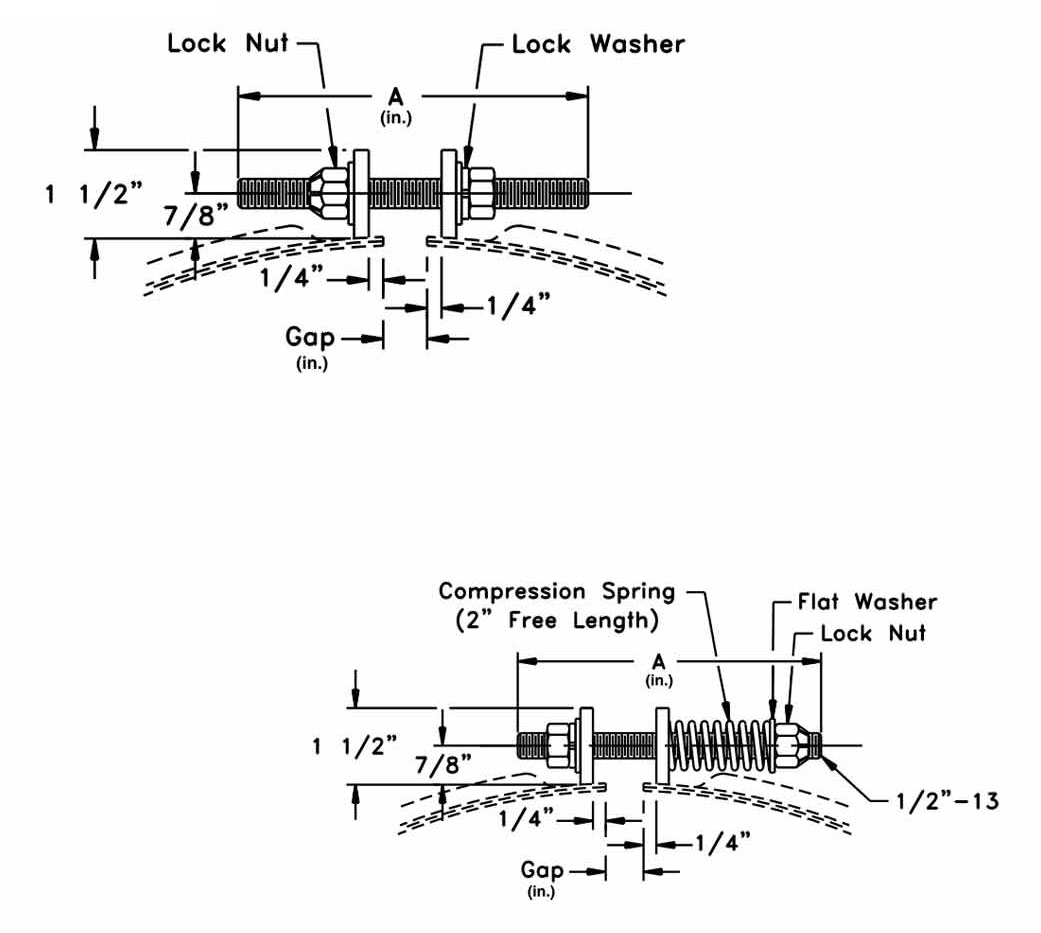

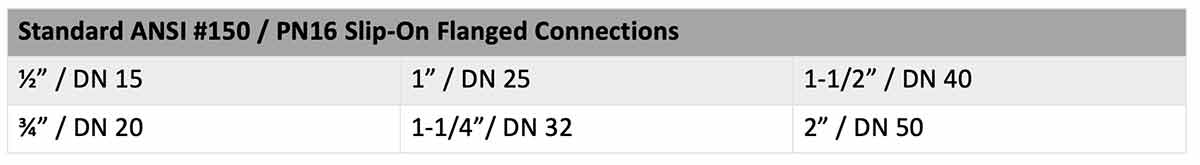

With each ECONOCOIL®, Delta T Thermal Solutions can offer a range of options and accessories to assist Installation and improve performance. For ECONOCOIL® to be used in tanks, we offer handles and hangers so they will be correctly positioned and can easily be inserted and removed. For clamp on applications, we offer Konduct No.1 Heat Transfer Cement to assist with heat transfer. Additionally, we supply lugs with tie bolts to securely fasten the ECONOCOIL® to surface sides.

If required, Delta T can provide job specific drawings & material certificates with other design and construction documentation on request.

Delta T can also supply special connections & flanges for the units. The table shows some standard flanged connections we can provide, but please contact us if you have a particular need.

ECONOCOIL® Curving & Custom Design

One of the robust design strengths of the ECONOCOIL® is its ability to be altered and molded to match specific needs and dimensions. The irregular-shaped area can have made to match panels utilizing as much space as possible.

Tank temperature maintaining is a typical application, so Delta T can curve ECONOCOIL® plates to match specific tank diameters. The units then comfortably fit and make use of all area available for heat transfer.

Needs Beyond ECONOCOIL®? — Turn to PLATECOIL®

For design needs and conditions which exceed our ECONOCOIL® specifications, Delta T manufactures PLATECOIL®. While ECONOCOIL® is hydraulically formed, PLATECOIL® is die formed. One or both sheets are pressed to form embossings (single or double) which are then seam welded together along the embossings forming clearly defined tubular channels.

ECONOCOIL® And PLATECOIL®

Both heat exchanger types are available in standard styles 50, 60, 70, 80 & 90 with widths of 300mm to 1200mm and lengths of 600mm to 3600mm. Units can be curved to fit specific tanks and are available with a variety of accessories such as handles, hangers, and lugs for easier installation. Plates can be banked for larger heating and cooling applications. Custom shapes and designs can be created with each format.