Platecoil ®

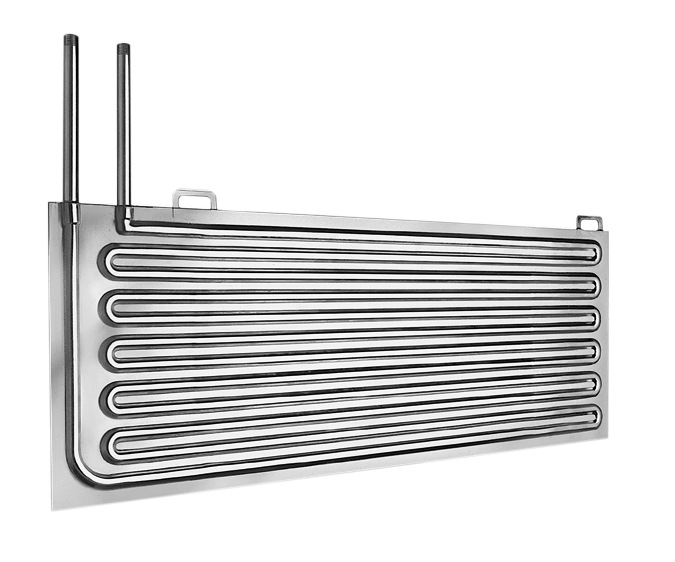

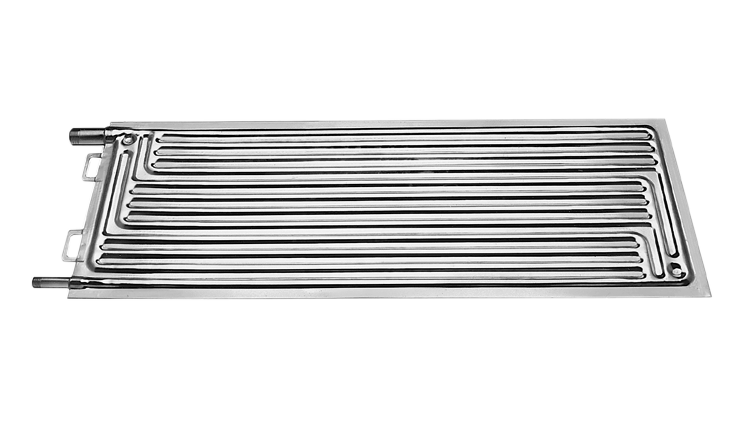

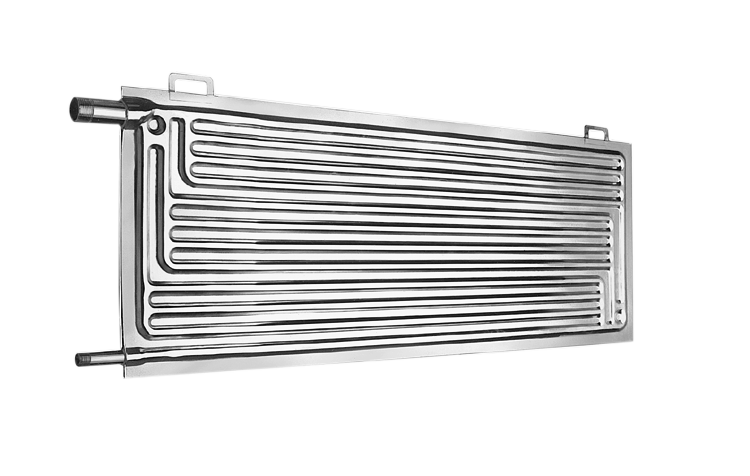

PLATECOIL® Heat Exchangers combine flexibility and functionality to deliver more efficient, economical and uniform heating and cooling to any application. Customers worldwide improve performance with panels bent, rolled, or otherwise formed into wide-ranging configurations. These highly versatile heat exchangers adhere to the highest standards for design, manufacture, and testing in the industry.

Delta T Thermal Solutions PLATECOIL® is a very efficient and versatile light-duty plate-type heat exchanger. Its unique construction enables high heat transfer efficiency for heating and cooling, which can be applied to a wide range of applications. Units are commonly used in the plating, metal finishing, chemical processing, pulp & paper, waste treatment, textiles, pharmaceutical, and food & beverage industries.

PLATECOIL® is fabricated from two sheets of metal using a fully computerized welding machine that uses electric roll spot resistance welding. The plate is then hydraulically inflated, forming a variety of flow patterns. Each ECONOCOIL® plate is designed and constructed to match the needs of each application and requirement.

With success stories spanning 70-plus years, PLATECOIL® versatility finds its way into new applications and industries each year.

PLATECOIL® Applications

- Immersion Heaters and Coolers

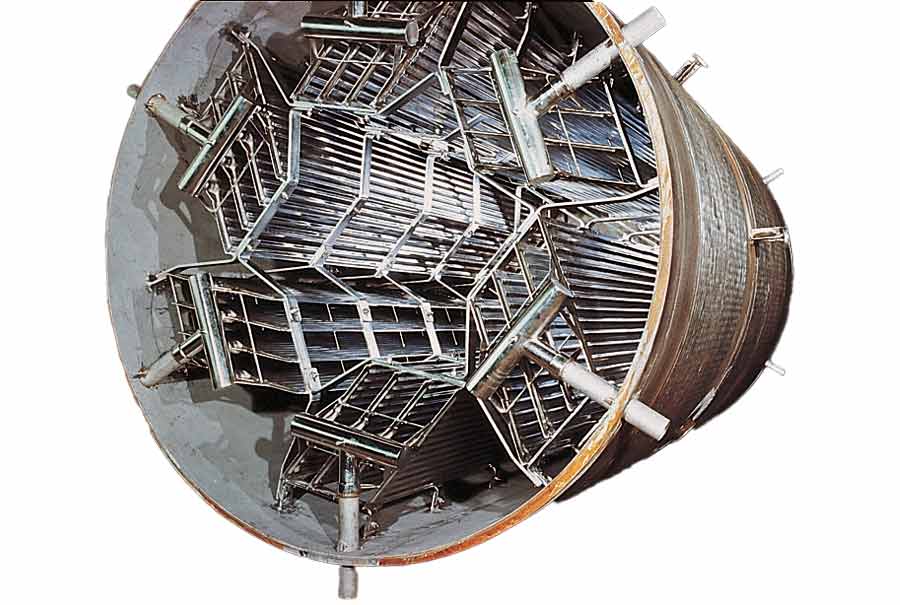

- Jacketed Tanks and Vessels

- Clamp-On Upgrades

- Heat Recovery Banks

- Fluidized Bed Banks

- Cryogenic Shrouds

- Cascade Coolers

- Freeze Dry Condenser Banks

- Shipboard Heaters and Coolers

- Storage Tank Heaters

- Shelves

- Glycol Dehydrators

- Paint Solvent Coolers

- Water-Cooled Shields for Electric Furnaces

- Water Chillers for Soft Drink Carbonators

- Valve Warmers

- Banks for Waste Heat Recovery

- Refrigeration Coolers

- Refrigerated Liners for Medical Testing Machines

- Suction Heaters

- Screw Conveyer Troughs

- Bayonet Heaters

- Drum Warmers

- Pipe Coolers

- Gas Cylinder Heaters

- Sanitary/Hygienic processing

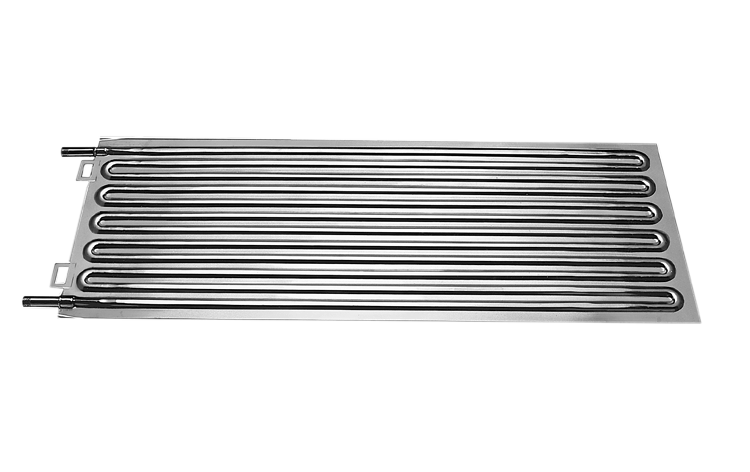

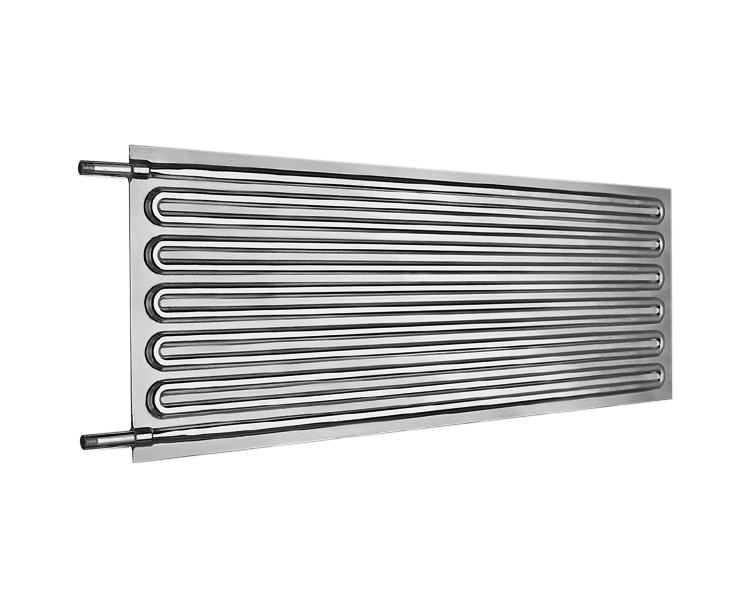

Double & Single Embossed PLATECOIL®

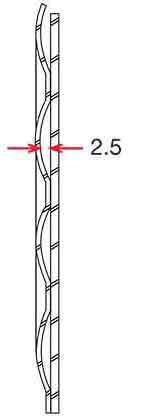

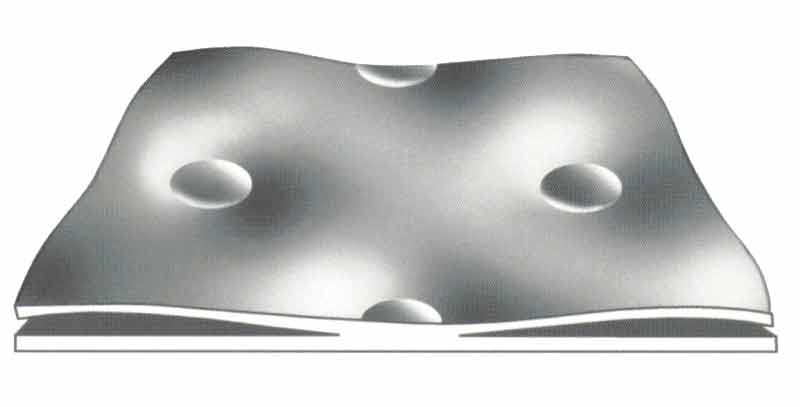

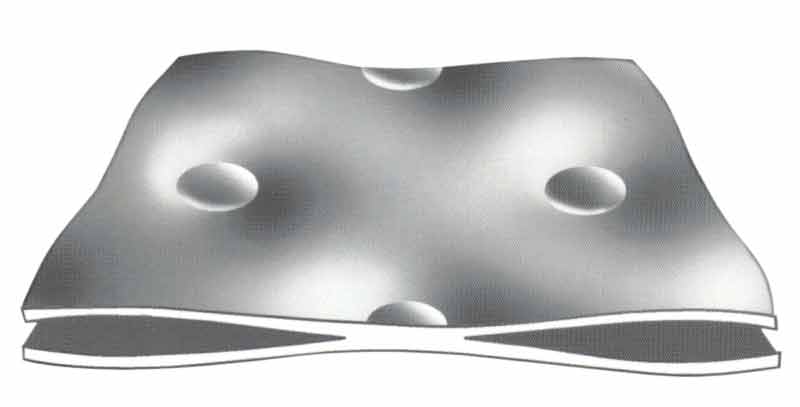

There are two main types of PLATECOIL®, which determine the unit’s structure. These are double embossed and single embossed.

Single embossed units are made from two sheets with different thicknesses. When inflated, only the thinner sheet expands, leaving one side flat. This is ideal for clamping onto tank walls, both internally and externally.

Double embossed units are made from two sheets of the same thickness, so when inflated, both sheets expand and form a symmetrical structure. These are generally used for internal tank heating plates and banked units.

PLATECOIL® is an embossed channel and is die formed while ECONOCOIL is hydraulically formed (inflated). Because PLATECOIL is die formed, it produces higher efficiency than ECONOCOIL®.

Die Formed PLATECOIL®

Hydraulically Formed ECONOCOIL®

Engineering of PLATECOIL®

Whatever your heating or cooling needs, we can engineer and fabricate a PLATECOIL® heat exchanger to improve your process and efficiency.

- Configurable as jacketed vessels, clamp-on panels, immersion heaters, banks-in-tanks, cryogenic shrouds, mixers

- Single-embossed or double-embossed styles may be flat, formed or rolled

- Wide range of pre-engineered and custom designs and sizes

- Unique Multi-Zone and Serpentine configurations available

- High heat transfer rates

- Quality manufactured and thoroughly tested; ASME Code available

- Fabricated in carbon steel, stainless steel and most corrosion resistant alloys

Manufacturing of PLATECOIL®

- Sheet material is pressed to form “corrugations” called embossings.

- Embossings are either seam welded to each other to form “double embossed” coils, or to a flat sheet to form “single embossed coils.

- Fittings are attached to provide an inlet & outlet for fluid internal to the PLATECOIL®.

- Carbon steel, 304 and 316 stainless steel are the standard materials of construction.

Other alloys that can be cold formed and welded are also used:

- Monel

- Inconel

- Hastealloy

- Alloy 20Cb-3

- 254-SMO

- AL6XN

- Titanium

Resistance Welding of PLATECOIL®

- Continuous electric resistance welds are used for perimeter and pass joining

- Machine welds are consistent, accurate & not susceptible to the human error of manual welding processes

- Weld wheels apply electrical and mechanical pressure from BOTH SIDES of the Plate

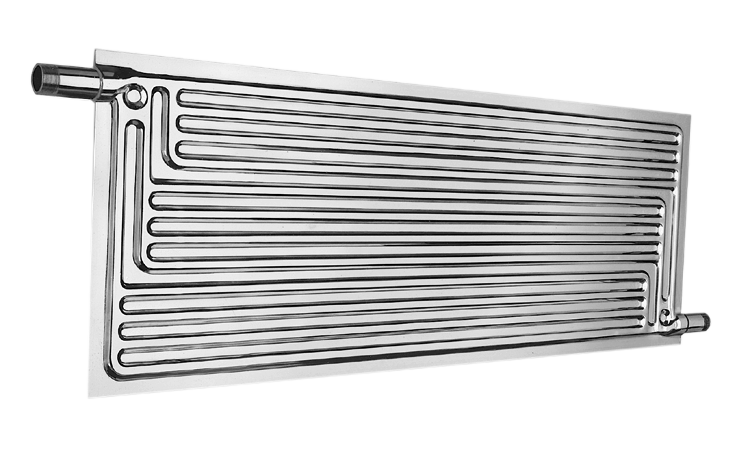

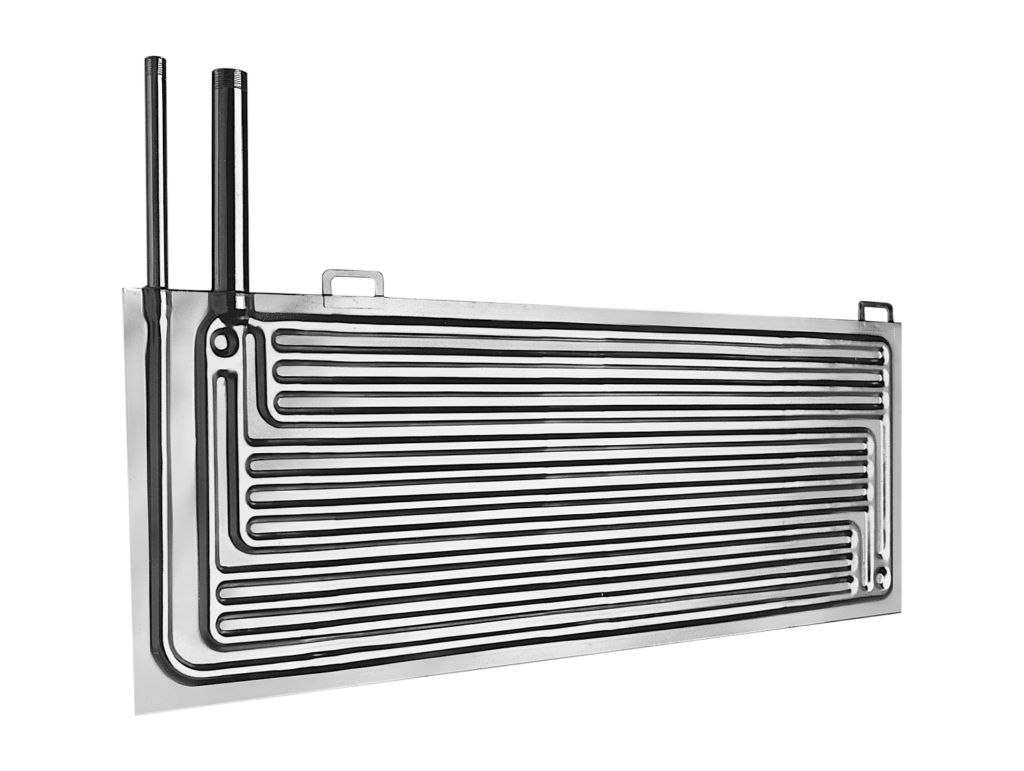

PLATECOIL® Styles and Explanation

Multi-Zone

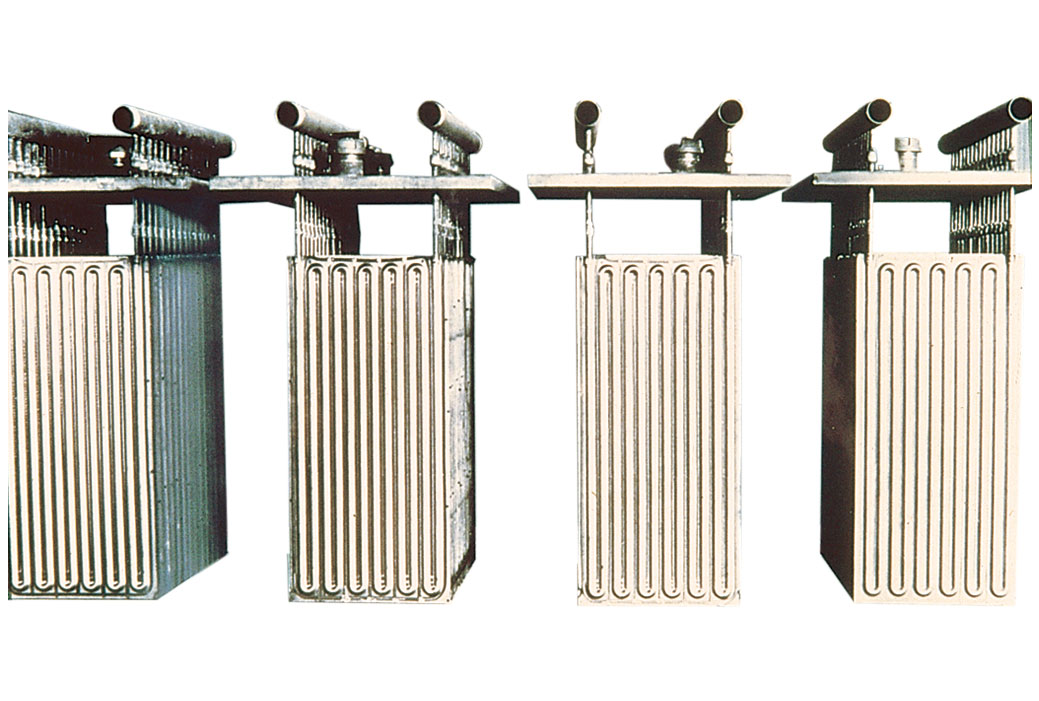

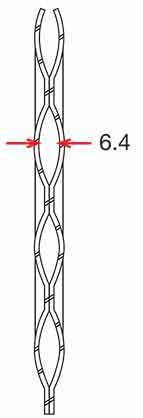

The passages formed by the embossings are designed to provide PLATECOIL® users with a choice of two basic flow patterns, depending on the application. PLATECOIL®’s Multi-Zone flow configuration is ideal for use when steam is the heating medium. The Serpentine flow configuration finds wide application with liquid heat transfer media such as water, oil and liquid refrigerants.

With its zoned header design, Multi-Zone PLATECOIL® provides far more heat transfer efficiency than pipecoil or units with straight headers in applications requiring the use of steam. The Multi-Zone headers and flow arrangement provide controlled distribution of the steam as it flows through the PLATECOIL®. The rate of condensate removal from the passages or passes is significantly increased as compared to units with straight headers. Efficiency reducing condensate blocking is minimized. As a result, Multi-Zone PLATECOIL® provides faster heat-up and better heat transfer rates.

Serpentine

PLATECOIL® with a Serpentine flow configuration provides outstanding performance with liquid heating or cooling media, because its configuration allows high internal flow velocities to be achieved. As a result, high heat transfer rates can be obtained. Serpentine PLATECOIL® is frequently specified for use with cold water, high temperature hot water, hot oil and refrigerants. When used with refrigerants, the Serpentine flow design offers the additional advantage of eliminating the possibility of “short-circuiting”.

Standard Styles, Sizes & Fabrications

Both Multi-Zone and Serpentine double-embossed PLATECOIL® are available in over 300 standard sizes. Several styles are also offered in a choice of either carbon steel or Type 316L stainless steel. Standard PLATECOIL® are available in over 300 sizes; widths range from 12” to 43”. Length dimensions range from 23” to 143”.

A variety of standard PLATECOIL® fabrications, such as drum warmers, vessels, suction heaters, and screw conveyor troughs are also available. These pre-engineered units are designed to satisfy a wide range of heating and cooling requirements in industrial process applications.

Special Designs Features

PLATECOIL® can be bent, rolled, or otherwise formed into virtually any configuration. It has inherent flexibility. In addition to carbon steel and stainless steel, PLATECOIL® can be fabricated from such materials as Monel, nickel and a variety of other corrosion resistant materials. Flow configurations, other than Multi-Zone and Serpentine, can be specified to meet special design and performance requirements. Several types of surface finishes can be provided to minimize fouling and reduce maintenance. Large pass, heavy gauge PLATECOIL® is another option available to satisfy requirements for high internal flow rates, low pressure drops and rugged use.

A variety of standard PLATECOIL® fabrications, such as drum warmers, vessels, suction heaters, and screw conveyor troughs are also available. These pre-engineered units are designed to satisfy a wide range of heating and cooling requirements in industrial process applications.

PLATECOIL® Accessories & Options

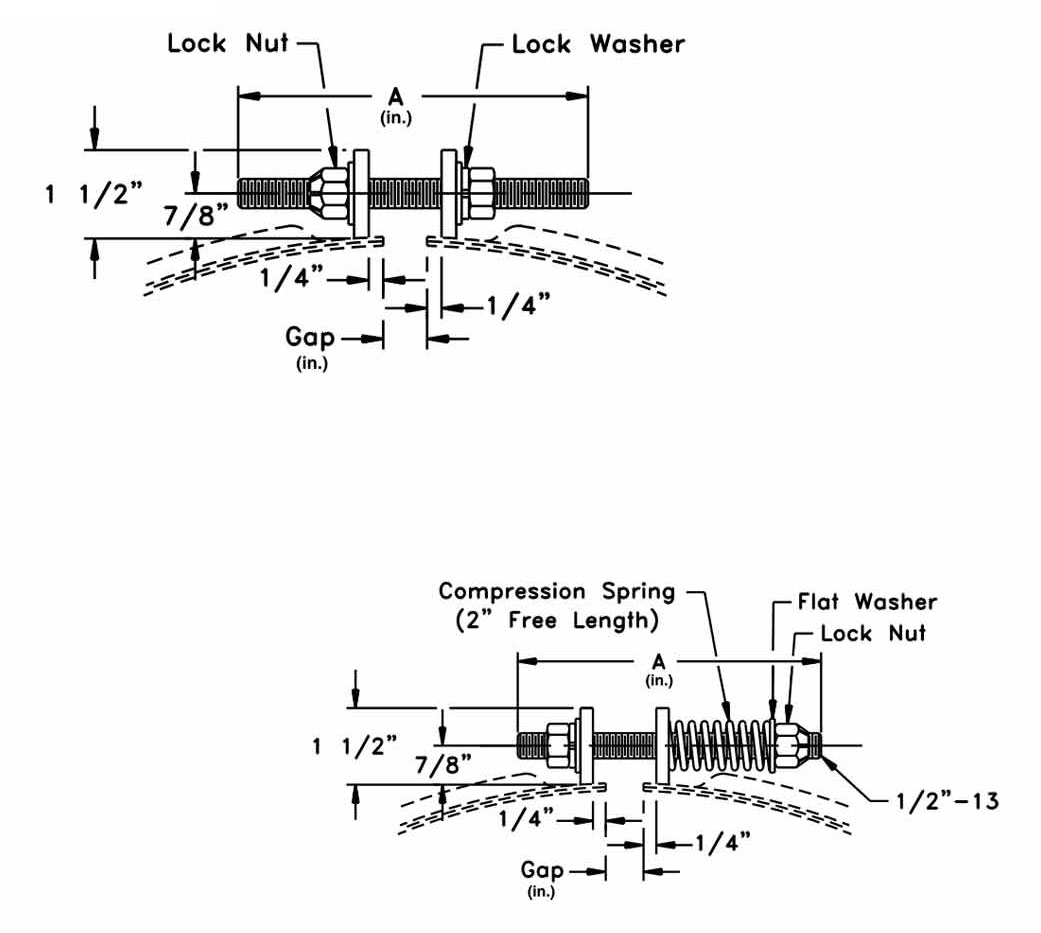

With each PLATECOIL®, Delta T Thermal Solutions can offer a range of options and accessories to assist Installation and improve performance. For PLATECOIL® to be used in tanks, we offer handles and hangers so they will be correctly positioned and can easily be inserted and removed. For clamp on applications, we offer Konduct No.1 Heat Transfer Cement to assist with heat transfer. Additionally, we supply lugs with tie bolts to securely fasten the PLATECOIL® to surface sides.

If required, Delta T can provide job specific drawings & material certificates with other design and construction documentation on request.

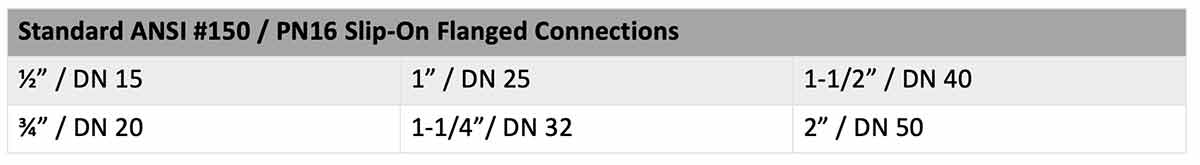

Delta T can also supply special connections & flanges for the units. The table shows some standard flanged connections we can provide, but please contact us if you have a particular need.