Marine

Reliable and efficient thermal systems are vital when a crew is far away from a port. Delta T offers many solutions for heat exchange marine applications.

Marine HE Applications

- Large yachts

- Supertankers

- Offshore rigs

- ATBs

- Cruise ships

- Freighters

- Naval vessels

- FPSO vessels

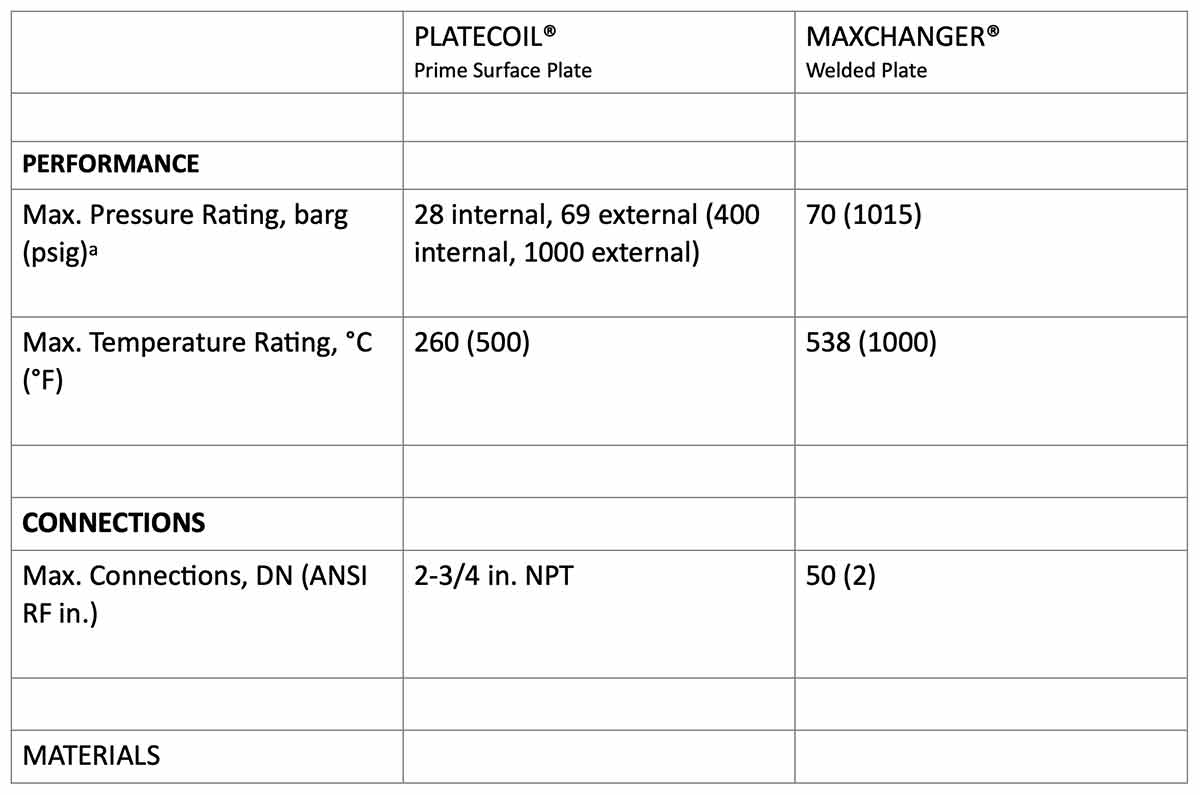

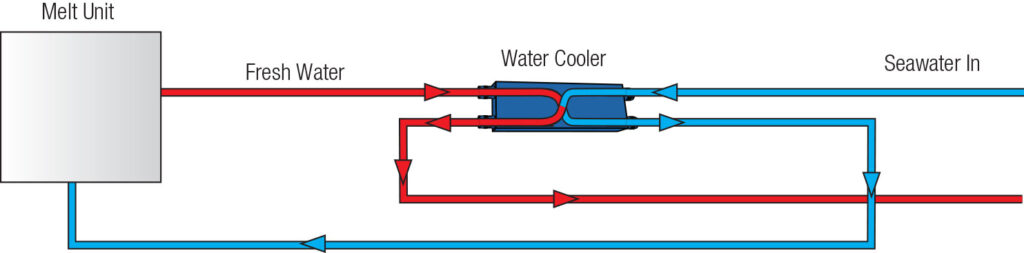

PHE Standard Range General Specifications

PLATECOIL® Prime Surface Plate

- Multitude of design configurations and more than 300 different sizes

- Versatility in providing heating and/or cooling

- Surpass field-fabricated linear pipecoil in initial cost economy and thermal performance

- Available in carbon and stainless steel, titanium and higher alloys

- Conform to ASME, U.S. Coast Guard, DNV, ABS and Lloyds Register codes

MAXCHANGER® Welded Plate

- Use where space is a premium or where gaskets cannot be used

- Efficiencies are comparable to a plate & frame HE

- Numerous alternate fitting locations and mounting configurations

Plate Box Coolers

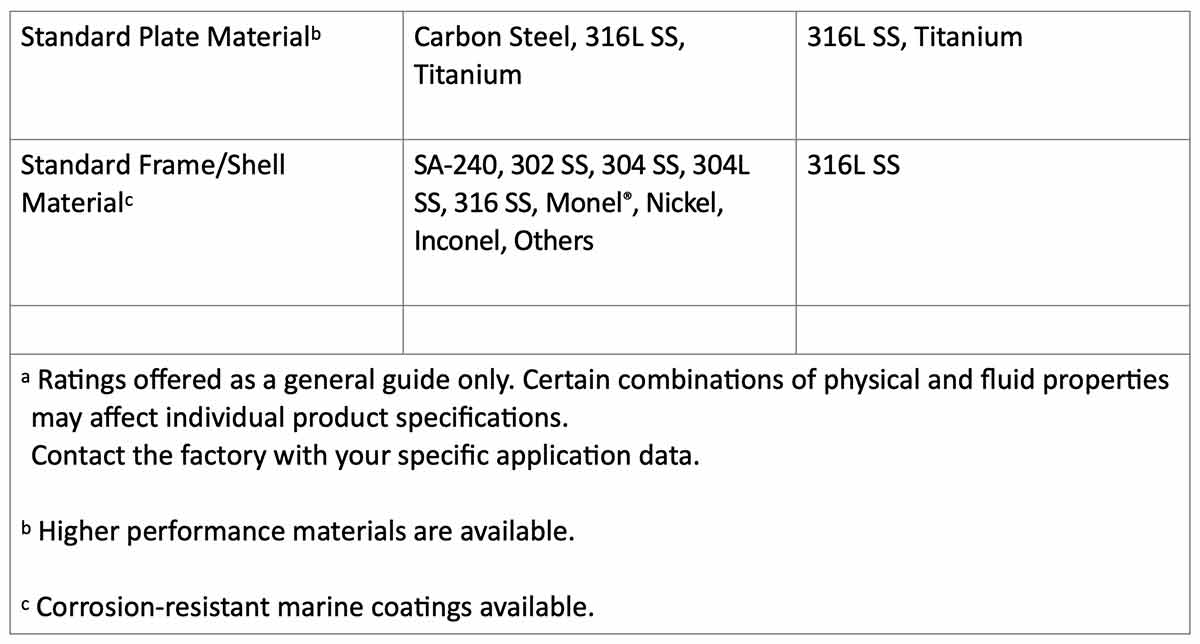

A bank of titanium PLATECOIL® panels installed in a vented sea chest transfers heat from the shipboard cooling circuit to external seawater, returning cooled fresh water to a storage tank for a variety of cooling purposes.

Cargo Heating

PLATECOIL® banks, installed in cargo holds, maintain cargo temperature at 33°C to 160°C (93°F to 320°F) using steam, hot water or thermal fluids. They are easier to clean, lighter weight, install very quickly and do not interfere with coating application in cargo holds.

Plastic Waste Disposal

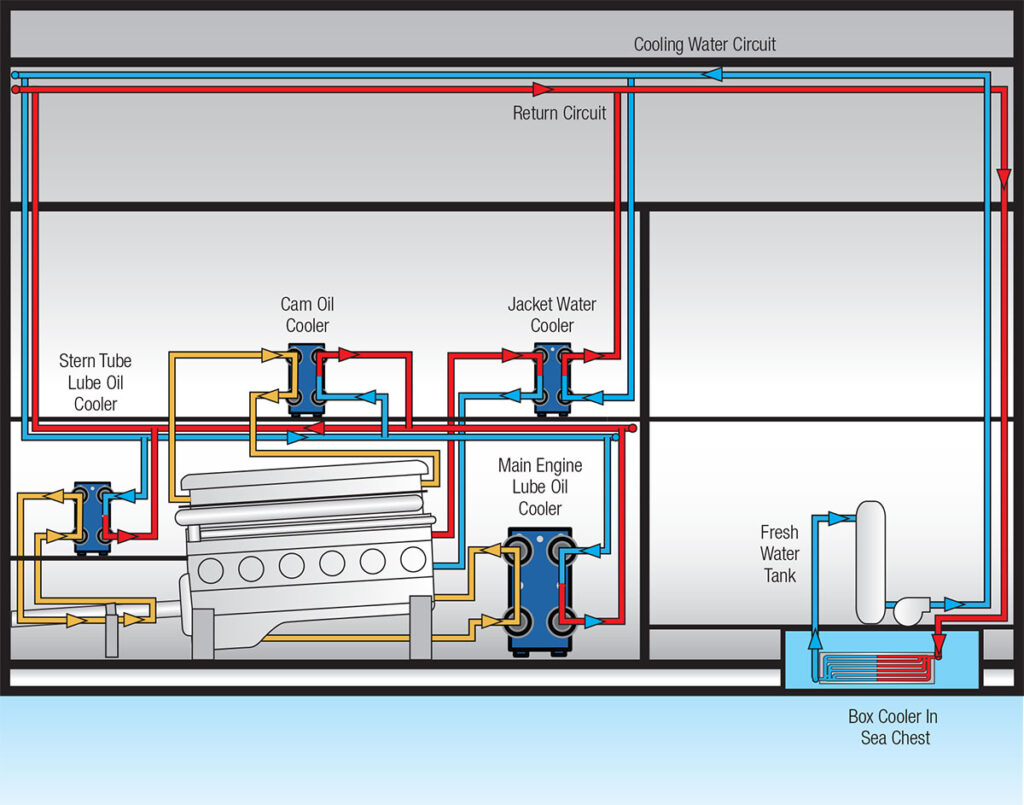

Hundreds of compact MAXCHANGER® units are installed on U.S. Navy ships to process plastic waste. They are used to cool a circulating water loop, which solidifies the plastic waste once it has been melted and compressed. Since seawater is the cooling media, titanium plates are necessary. But it was their light weight, small space requirements and maintenance-free construction that sold MAXCHANGER® units for this application.

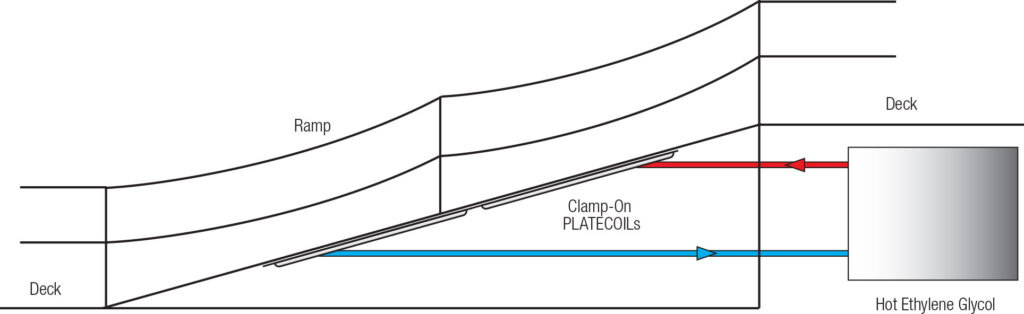

Superstructure And Gangway De-Icing

PLATECOIL® Prime Surface units have been used beneath deck ramps on board ships to prevent icing during cold weather. Single-embossed PLATECOIL® panels, circulating hot ethylene glycol, are attached to the underside of the deck ramp to keep them ice free. They are also used to heat ship superstructures, reducing above-waterline weight caused by ice.

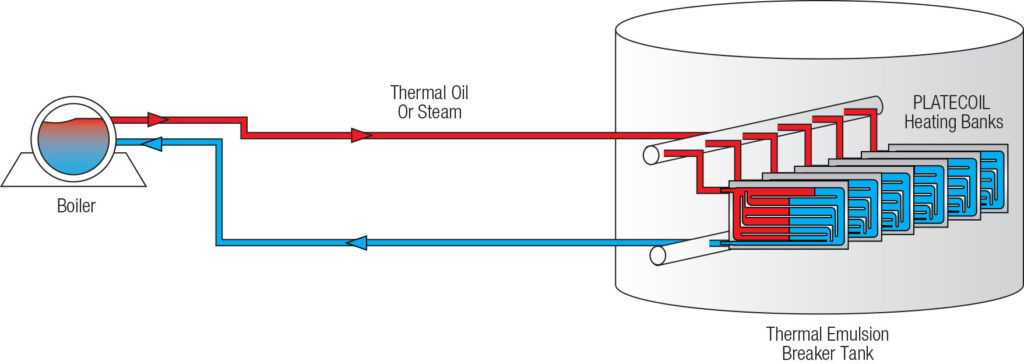

Thermal Emulsion Breaking For Recovered Oil

Recovering spilled oil is an important job made a lot easier with PLATECOIL® Prime Surface Heat Exchangers. PLATECOIL® banks heat heavy, recovered crude oil to separate oil from water and facilitate pumping out of the hold. And banks of PLATECOIL® units are easy and economical to install

and maintain.

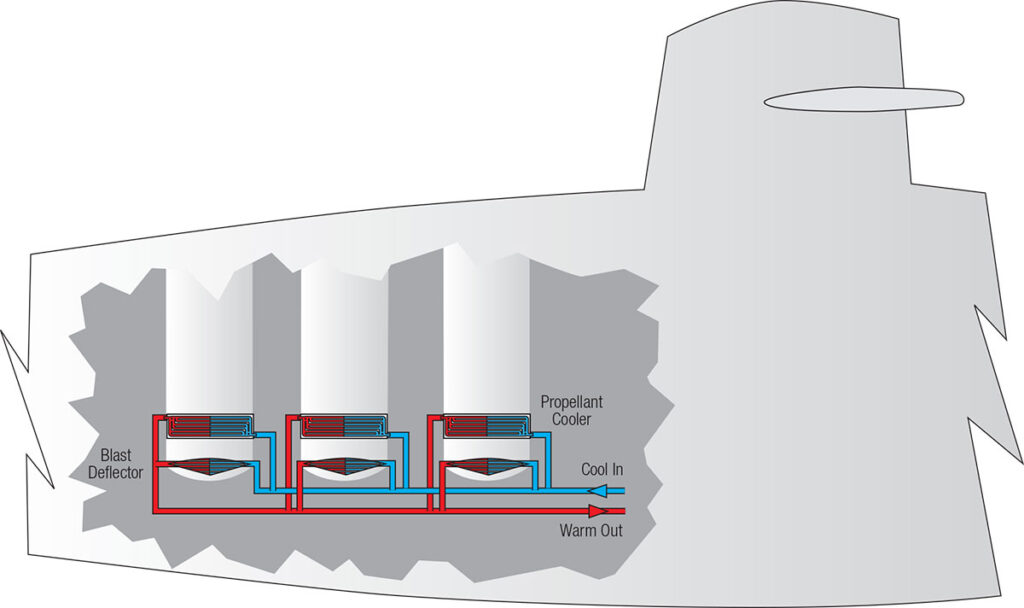

Temperature Control On Missile Tubes

PLATECOIL® units, formed to the diameter of missile launch tubes, closely control the temperature of the solid propellant used in ICBMs deployed in the Trident II Missile Submarine Fleet. Also, PLATECOIL® blast deflectors are used within launch tubes to facilitate hot missile launches.

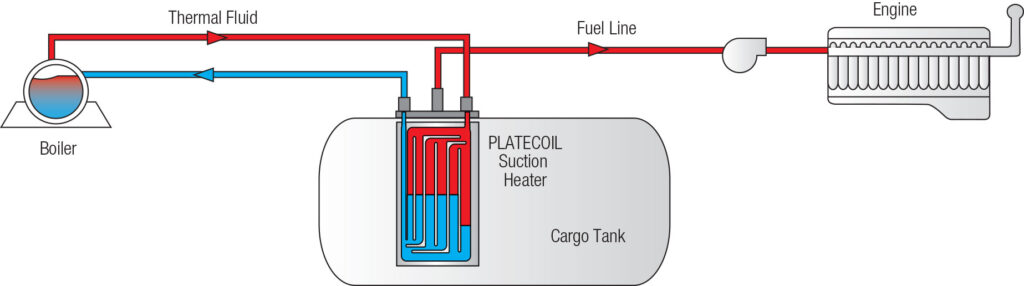

Suction Heaters

Box chamber suction heaters prefabricated from PLATECOIL® comprise a more compact design approach than electric or hot oil whole-tank heaters. They employ the pump inlet as the heat source instead of the entire tank. Additionally, the hot suction heater walls help preheat the viscous liquid before it enters the pumping chamber, improving pumping efficiency. An alternate design uses PLATECOIL® fabricated into a cylinder, with the suction extended through the center.

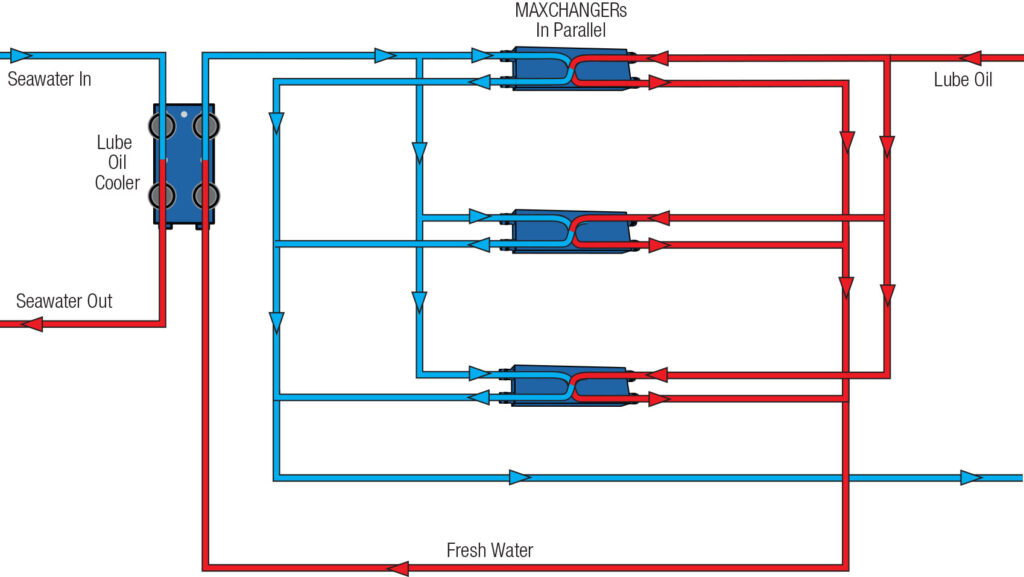

Lube Oil Cooling For Gas Turbine Powered Ships

Three MAXCHANGER® units in parallel effectively cool engine lube oil. The advantage of this configuration is that the lube oil heat exchanger loop never needs to be opened. Cleaning is performed only on the seawater gasketed plate heat exchanger where bio-fouling can occur.